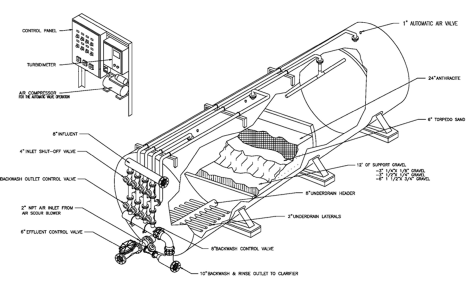

The MLF Multiplex Filter is a granular bed filter of the enclosed type. In its most

common form it consists of fup to 8 individual filter compartments, each containing

specially prepared and graded filter media. The type and gradations of the media

employed are varied, depending on the particular influent water to be treated and

other factors. The design is such that the filter may be supplied with water from

either a pressure or gravity source.

During normal service operation water enters the top of each compartment through

a separate inlet distributor and flows downward through the filter media to the common

underdrain system. The underdrain usually consists of a single header, fabricated

integral with the vessel, to which laterals are attached. This underdrain evenly

collects the flow, which leaves the unit through a common outlet connection. When

backwashing is required to remove entrapped particulate matter, the inlet valve to

one filter compartment is closed and the backwash outlet valve of that compartment

is opened. The water continues to flow downward through the three remaining cells

and upward through the fourth. The bed is fluidized and the flow rate is maintained

to provide optimum scrubbing and cleansing action. Backwash water is drawn off through

the upper distributor and flows to waste. This operation is continued for each of

the other three compartments. After all compartments have been backwashed and before

the filter is returned to service, it is rinsed to waste. This insures that the

filter beds have been properly resettled and that the unit is producing a high quality

effluent prior to its being returned to service.

Typical applications include:

Mining/Tunneling operations

Municipalities

Industrial

Markets